Gypsum is used to prevent immediate stiffen and reduce heat loss of a cement. As the promoters of the technology state producing LC3 cement does not require capital intensive modifications to existing cement plants and produces binders with the same performance as OPC.

Concrete Training Courses Workability Of Concrete Concrete Mix Design Concrete Concrete Column

Stowage factor for bulk cement is 061-064 m 3 t.

Clinker cement factor. The alumina ratio 1327 alkali contents Na 2 O and K 2 O each 02 per cent and the degree of sulfatisation were varied. The above three parameters are those most commonly used. The clinker factor varies from 783 to 729.

The results show that the optimal clinker factor is at 745 with the CGA addition 300 ppm. Nowadays the clinker-to-cement factor is defined by standards as well as type and amount of SCM that can be added the more widely used being slag fly ash and pozzolan. The clinker factor reduced to 071 in 2017 from 074 in 2010.

Published in Global Cement News. This burning produces rough cinder lumps that are later crushed to a fine powder to produce cement. LC3 cements 5 have a clinker factor of only 50 with the rest being 30 calcined clay metakaolinite 15 limestone and 5 gypsum.

What is clinker factor. Clinker C3S C2S C3A C4AF. It is generally accepted that the production of 1 t of ordinary Portland cement OPC creates over 800 kg of CO 2.

The primary motivation is to reduce the energy consumption and CO 2 emissions associated with cement clinker production in rotary kilns. Contamination with sea water will increase the chloride content of the clinker and the cement. In August 2018 the Global Cement and Concrete Association GCCA said it was taking over the work previously done by the CSI from 1 January 2019.

It can improve the cement fineness to 3848cm2gr and decrease the sieving R45μ to 10. The rough cinder lumps are called clinker and are shipped in this form to avoid the difficulties of carrying cement powder. Limestone is largely employed and conventionally defined as non-reactive filler even if a synergistic reactivity when combined with other additions has been recently.

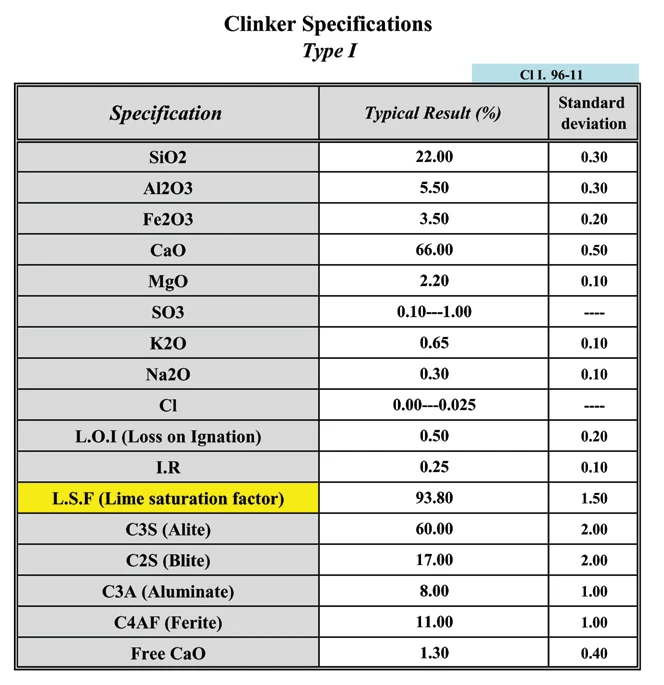

A fourth the Lime Combination Factor LCF is the same as the LSF parameter but with the clinker free lime content subtracted from the total CaO content. Burnability index for clinker Burnability factor for clinker Burning temperature minimum Go To Online Calculators. Clinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products.

Clinker is a nodular material which is used as the binder in cement products. The results show that the optimal clinker factor is at 745 with the CGA addition 300 ppm. Cement is a binding agent that sets and hardens to adhere to building units such as stones bricks tiles etc.

The lumps or nodules of clinker are usually of diameter 3-25 mm and dark grey in color. Lime Saturation Factor - Cement Plant Optimization Lime Saturation Factor LSF Lime Saturation Factor LSF is the ratio of the actual amount of lime in raw mealclinker to the theoretical lime required by the major oxides SiO2 Al2O3 and Fe2O3 in the raw mix or clinker. Cement clinker is the semi-manufactured material usually very hard grey granules between 1 and 20 mm in diameter.

It can improve the cement fineness to 3848cm2gr and decrease the sieving R45μ to 10. The incentive to reduce the clinker factor in cement products is two-fold. In ordinary Portland cement clinker the AR is usually between 1 and 4.

28-days mortar strength Mpa. This means that c155 tonnes of raw mix are required and c055 tonnes of CO2 are lost due to calcination of the CaCO3 in the raw material. It is produced by heating limestone and clay to the point of liquefaction at about 1400C-1500C in the rotary kiln.

Investigations have been carried out on laboratory clinker made from cement raw meals with a uniform lime saturation factor of 93 per cent and a silica ratio of 24. Hence it is a virtual cement production under the assumption that all clinker produced in a plant is consumed for cement production in the same plant and applying the real plant specific clinkercement factor. The clinker factor varies from 783 to 729.

The lime saturation factor LSF is a ratio of CaO to other oxides it is used to control the proportion of cement raw meal. Low Clinker Factor could affect Cement Quality and Performance Increased fineness of Cement result in Increased Power Consumption Decreased Cement Mill Thru-puts May affect Concrete Performance at site and against the Competitor Products in Market. Is a cement production value which is determined from clinker produced on-site applying the plant specific clinkercement-factor.

Clinker is a granular substance containing spherical pellets of diameter 3-25 mm. It is substantially unaffected by water but should be kept dry to avoid caking. The clinker factor is therefore 065 x the amount of raw mix.

The majority of Portland cement clinker manufactured around the world has a lime saturation of between 90 and 100. Raw Mix to Clinker ratio RC Go To Online Calculators. Cement C3S C2S C3A C4AF.

Cement is such a fine powdery substance that each pound of. The high saturation ratio will make the raw meal difficult to burn to clinker. In the operation of the cement kiln the thermal system of the kiln can be affected by the fluctuation of LSF.

In addition the strength of the cement produced is higher than the standard. Cement is formed by burning limestone with clay.

Cement Clinker Quality Control During Clinker Production Process Agico

Difference Between Clinker And Cement Civilengineer Online Com

Characteristics Of The Industrial Cement Raw Mix And The Produced Clinker Download Table

Top Cement Consuming Countries Download Table

Portland Cement Clinker Type Ii And I 42 5 And 52 5 Buy Cement Clinker Portland Clinker Clinker Price Product On Alibaba Com

Cement Training Course In Powerpoint Civil Engineering Engineering Programs Civil Engineering Software

Parameter Values For The Cement Manufacturing Process Download Table

Concrete Estimate Formula Excel Spreadsheet Concrete Mix Design Concrete Column Concrete

The Output Of Cement Clinker Cement And Clinker Using New Dry Process Download Table

Mass Balance For Cement Production Download Scientific Diagram

Clinker Substitution Cembureau

High Quality Portland Cement Clinker Marketer Goodmax

Clinker Substitution Cembureau